The materials used to make PCBs are very important. Because the costs of different materials can vary from 10% to 100%, so the price difference of PCB made from different materials can be very huge. On the other hand, the function and quality of different materials vary. Here is a brief introduction of PCB materials.

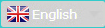

1. FR1-FR4

FR1 is basically the same as the FR2. But FR1 has a higher TG of 130, while FR2 105. Actually the cost and usage are very similar. So most of the manufacturers will choose FR1 rather than FR2. FR3 is very similar with FR2. But instead of phenolic resin it use epoxy resin. FR4 is the most commonly used PCB material; it is a glass fiber epoxy laminate. The Tg is around 120-130 oC. In China, the FR4 is the most widely used material because it can make all kinds of PCB and the management and quality control is much easier.

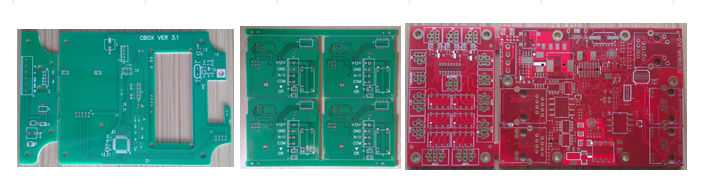

2.CEM1 and CEM3

CEM-1 is a paper-based laminate; it is not suitable for Plated through Hole and can be only used for one layer PCB. CEM-3 is very similar with FR4. It has white color and is very smooth. It can replace FR4, but not popular in China.

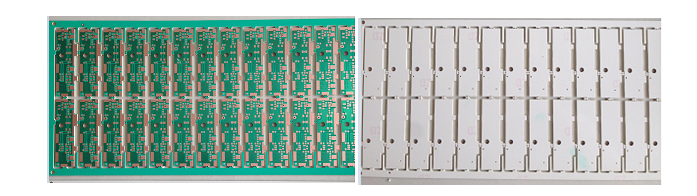

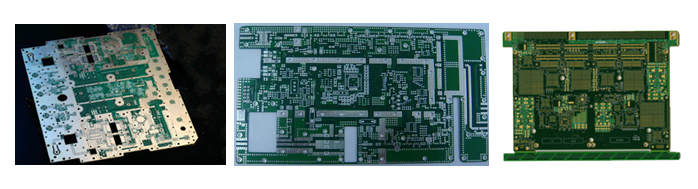

3.Metal Core

Currently the metal core mainly refers to: aluminum (aluminum core PCB), copper (copper core PCB or a heavy copper PCB) or a mixture of special alloys. The most common is an aluminum core PCB. With its advantages of dissipate heat, keeping heat generating components cooler which results in increased performance and life. It was widely used in LED applications.

4. PPE/Ceramic/PTFE

These material with super high Tg, the PCBs are mainly used in high performance RF, high reliability, high speed digital products. Currently we have customer in the Medical, test instruments, industrial control use these materials.