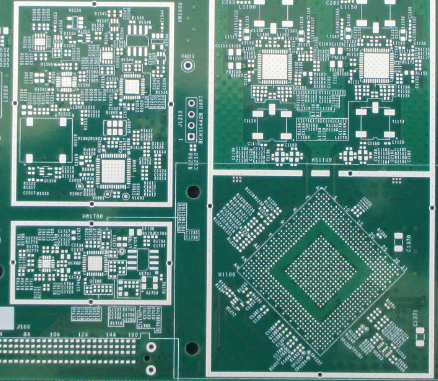

Anyone in the printed circuit board (PCB) industry understand that PCB’s have copper finishes on their surface. If they are left unprotected then the copper will oxidize and deteriorate, making the circuit board unusable. The surface finish forms a critical interface between the component and the PCB. The finish has two essential functions, to protect the exposed copper circuitry and to provide a solderable surface when assembling (soldering) the components to the printed circuit board. Today let’s look at the Immersion Silver.

What is Immersion Silver finish?

Immersion Silver is also called immersion Ag. It is the standard finish at Pandawill Circuits and is RoHS compliant. It is an improvement on HASL being exceptionally flat, and can replace Immersion Gold over Electroless Nickel (Au/Ni) for most applications. The use of Immersion Silver has no effect on customer’s assembly processes. The typical thickness 0.12 – 0.40um

Advantages:

- Immersion finish = excellent flatness

- Good for fine pitch / BGA / smaller components

- Middle range cost for lead free finish

- Can be reworked

Disadvantages

- Very sensitive to handling / tarnishing / cosmetic concerns – gloves must be used

- Special packaging required – if packaged opened and not all boards used, it must be resealed quickly.

- Short operating window between assembly stages

- Not recommended to use peelable masks

- Should not plug holes from one side only

- Reduced supply chain options to support this finish

Handling and Storage of Immersion Silver finished pcbs

- Avoid finger contact with the Immersion Silver finish. It is recommended that gloves be used for handling panels/boards.

- The generally accepted shelf storage life for Immersion Silver is 6 to 12 months in dry conditions, the same as that for HASL.

- If pcbs have been in storage for some time, it is wise to perform a solderability test prior to assembly. For SMD applications this might consist of solder paste and reflow of a bare pcb.